Company Profile

"Bond without Boundary"

As a leading performance textile supplier, Tiong Liong Corporation (TLC) has been offering performance fabrics for over 40 years by means of eco-friendly processing techniques and smart manufacturing. Thanks to the seamless integration of design, R&D and production, our supply chain is more sustainable than ever.

As a leading performance textile supplier, Tiong Liong Corporation (TLC) has been offering performance fabrics for over 40 years by means of eco-friendly processing techniques and smart manufacturing. Thanks to the seamless integration of design, R&D and production, our supply chain is more sustainable than ever.

We are proud to support your business through a variety of core technologies, including weaving, dyeing and finishing, functional treatment, coating, and lamination. In response to the market needs, we expand our manufacturing capacity to China and Vietnam, providing faster and more agile localized production.

More than an ordinary textile supplier, we operate our own brand while serving as a proactive partner for international specialized materials, in which we benefit customers in all parts of the world with a diverse selection of materials and streamlined services.

Bond with Sustainability

We prioritize environmental protection and sustainability by adopting digitalized material development and prototyping processes. These practices reduce carbon emission, cut energy use, and prevent pollution, and the best thing is it speeds up design cycle by 50% without additional cost. The benefit of digitalized processes, on top of Global Recycle Standard (GRS) certifications, and the Higg Index verification system, adds more value to the partnership between TLC and customers.We make circular economy a reality by upcycling materials. ARIAPRENE® TERRA, a reborn foam recycled from mill waste, and MARINYLON®, made from decommissioned fishing nets, are the proof of our promise in extending product lifespan and maximizing the use of resources.

Bond with Productivity

We appreciate teamwork. We keep tapping on the latest market trend and putting a laser focus on future development. Our marketing and R&D team collaborate effectively and combine all-channel resources, developing innovative materials which fulfill current needs and future trend.We strive to link all production phases smoothly, enable an integrated supply chain and deliver the best experience through partnership. We gather raw materials from Taiwan and abroad to create critical value by efficient production at high quality smart factories.

Bond with Creativity

We believe that co-creation leads to outperformance. Our lamination technique is an excellent example, as it gives more functionality to a single material and exceeds customers’ expectations.We pool our expertise with industrial resources to invent and innovate. TLC’s winning team is both agile and creative, built on effective bilateral communication and include the latest technology to bring more possibilities in innovation.

TLC Milestone 1979~2019

1979 ~ 2000

● TLC was established in Taichung by Namliong Group. The footwear lamination manufactory starts to provide materials to NIKE®, adidas®, and Puma®.

● TLC receives full support from Bayer Group and becomes its agent in Taiwan for waterproof membrane products and cooperate with world-renowned material brands strategically, namely Sympatex®, Outlast®, BHA® (GE), X-Static®, etc. Additional water-based PU laminating machine added and become the agent of Permair® Leather and porelle® in Asia.

2001 ~ 2010

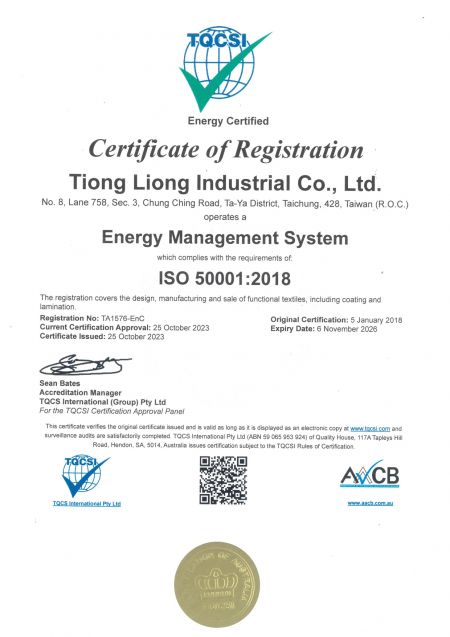

● TLC obtained ISO 9001 certification and become an agent of Outlast®.

● TLC cooperate with Symbatex and become the exclusive agent of the COLVERA® membrane.

● TLC Become an exclusive agent of event®, for footwear material and softshell for apparel.

● TLC qualified as TR1 supplier for NIKE® and adidas®.

● TLC Lab qualified by adidas®, DECATHLON®.

● TLC launch own brand ARIAPRENE®.

2011 ~ 2019

● TLC obtained NB® Brand Restricted Substances Certification.

● Zhongqing, Taiwan obtained ISO 14001 & OHSAS 18001 certification.

● TLC joined SAC. (Sustainable Apparel Coalition).

● TLC obtained the carbon footprint certification, PAS2050: 2011 and ISO / DIS 14067.

● TLC celebrate 40th Anniversary.

● Establish Tiong Liong Jiu Tian Educational Foundation.

● TLC joined members of the Better Cotton Initiative (BCI).

● FUQING, China obtained ISO 9001 & ISO 14001 certification.

● TLC acquire GRS (Global Recycled Standard) Certificate.

● Set up TLC Innovation Center.

● Approved by Nike for Footwear Textiles Vendor in Vietnam.

● Social and Labor Convergence Project (SLCP) verified assessment.

● D-U-N-S® Certificate (D-U-N-S® Num: 65-602-7422)

2021

● TLC launch own brand MARINYLON® .

Gallery

- TLC-Zhongqing Factory

- TLC-Hengshan Factory

- TLC-Qingquan Factory

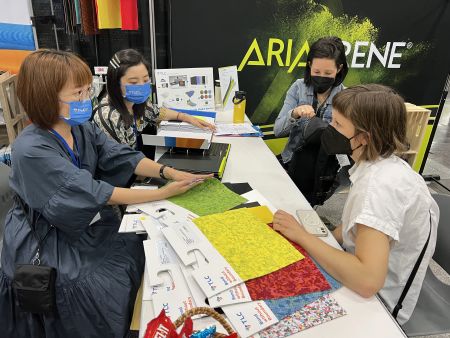

- TLC-2022 NW show

- TLC-Consensus Camp

- TLC-2022 Sustainability and Innovation Showcase

- TLC-2022 Sustainability and Innovation Showcase

- TLC-2022 Keelung City Expo

- TLC-Sports Products

- TLC-Sports Shoes

- Functional apparel

- TLC-Mt. Jade climbing

- TLC Activity-Golf Team

- TLC-Cycling Around Taiwan

- Certificates

.jpg?v=f378aace)